See this page.

Is this OK? I know that Pb-based solder is extremely creep-sensitive, so you don't want any force exerted on solder connections. That's why heavy components (think transformers or components mounted on a heat sink) should always have a mechanical fixing (screws) apart from the solder connections.

So for me it's a no-no. What do you think? Do other solders show less creep?

edit (re Fake's comment on snap-in)

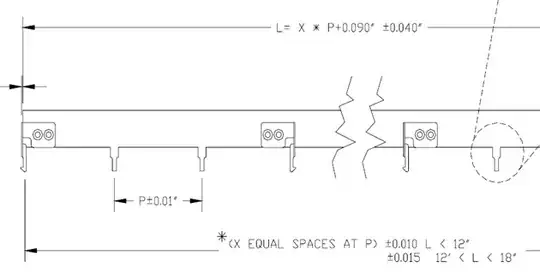

The snap-ins seem to be hooked pins which hold the bar in place (during soldering), as there are also soldering pins: